To overcome the difficulty of advanced packaging bubbles for AI chips! Printing Layout WMCM and CoPoS Technology

Imprint Technology announced today that it had an annual increase of 1.097 billion yuan in the first half of the year, an increase of 25.70%; its gross profit was 750 billion yuan, an increase of 37.87% year-on-year, a gross profit margin of 68.34%, and its business profit was 602 billion yuan, an increase of 42.99% year-on-year; its net profit after tax was 391 billion yuan, an annual decrease of 23.33%, and its pure equity per share (EPS) was 14.3 yuan, an annual decrease of 29.45%, due to one-time exchange.

Inner Technology closed 252 billion yuan in July, an increase of 76.01%, a new high in the same period last year; it is expected to close 1.349 billion yuan in the first seven months of this year, an increase of 32.79%, a new high in the same period last year, while earnings per share (EPS) of 14.3 yuan in the first half of the year, of which only 5.76 yuan was RMB 5.76 yuan in the second quarter, mainly due to the exchange losses caused by the sharp rise in New Taiwan Coins. Some customer payment coins will be adjusted in the future to reduce the impact of the exchange rate.

Inner Technology pointed out that the gross profit margin in the first half of the year was about 68.34%, higher than the 62.27% level in the same period last year, mainly due to the higher gross profit margin increase in new generation products and upgrade cases. The third quarter will enter the peak season, with July closing highs reaching the same period of the year, and the profit performance is expected to develop in a positive direction.

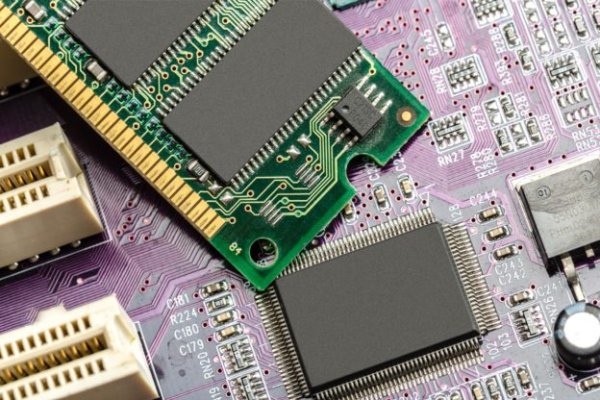

Print Energy Technology shares that AI semiconductor chips have strong demand. Apple will adopt WMCM packaging next year. Advanced packaging capacity of large-scale diesel foundry manufacturers is being fully expanded, among which CoWoS (Chip-on-Wafer-on-Substrate) capacity is clearly in short supply.

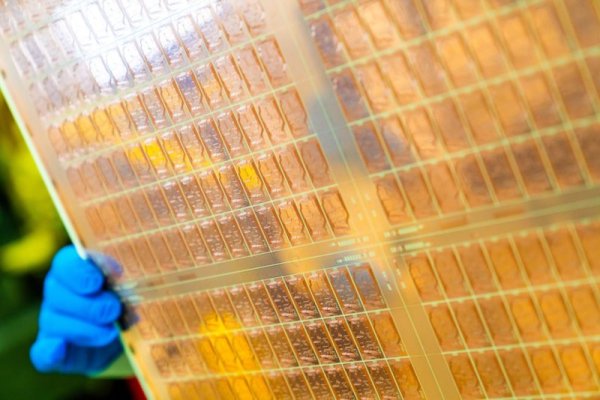

According to the TrendForce report, with the surge in orders for AI chips, the monthly production capacity of CoWoS in 2025 is expected to reach 75,000, almost twice that of 2024. However, in this advanced packaging, bubbles and skewers have always been the biggest concerns about yield. Related problems include the residual bubbles in the packaging material that can cause weld spots to be hollowed out, welding failure, component overheating or structure impairment, and skewers will make the alignment of the multi-wafer chip difficult, thereby reducing overall production efficiency and product life.

In this regard, Printing provides a comprehensive solution with high-voltage vacuum defoaming technology, high-voltage vacuum welding and flexural suppression system (WSAS). The new WSAS equipment can effectively suppress flexural in wafer and panel-level packaging, and has been successfully applied to improve the yield of 3D Hybrid Bonding.

Printing Technology has emphasized that in order to help packaging manufacturers overcome the problem of bubbles and chip flexures in advanced AI chip packaging, significantly improve volume yield, and meet the strict requirements of packaging reliability in the high-speed computing era, Printing Energy Layouts WMCM and CoPoS (Chip-on-Panel-on-Substrate) supply chains.

Printing Technology emphasizes that CoPoS adopts 310×310mm square panels, replacing 12-inch wafer rounds, and its production capacity has been increased several times. WMCM is an InFO-PoP upgraded version, integrating CoW and RDL technologies, integrating efficiency and heat dissipation, meeting the needs of high-speed computing. The outlook for orders has extended to 2026, and the operation prospects are expected to be continuously happy.

Extended reading: Unrealized impact! Zhiwei Season 2 receives unmanned airports with 24 million subsidies and still be reduced to 3.36 yuan The second season of the Exploration in the Slam Strike is RMB 0.71! American smart eye lens, uninhabited machine single-only Zhending has grown significantly due to high-level AI order demand! Shen Qingfang: The capital expenditure in these two years reached 3 million yuan