Gathering outstanding alumni from the technology industry, the 5th Chengdu Forum focuses on smart manufacturing and service innovation under digital transformation

The National Cheng Kung University "Chengdian Forum", which has entered its fifth year, was grandly held on the 10th at the Xunhui Lecture Hall of the Department of Electrical Engineering of the school. The forum was themed "Smart Manufacturing and Service Innovation under Digital Transformation" and specially invited 6 outstanding alumni to return to school during the school anniversary to share their valuable experiences. Through actual cases, we will explore in depth how to use technologies such as big data and artificial intelligence to effectively transform data into decision-making basis, thereby improving production efficiency and value, and promoting breakthroughs and development in smart manufacturing and service innovation.

In his opening speech, National Cheng Kung University President Shen Mengru said that where the university is, hope lies. The school is a place where everyone’s hope is nurtured, and after-sales service will allow the campus to continue to be an important platform for knowledge exchange. The exciting and fulfilling Chengdian Forum has entered its fifth year. Similar forums on campus include Chengcai Forum, Chengji Forum…, etc. In fact, they can be successful forums. The semiconductor industry is a huge ecological chain, in which alumni from various departments of National Cheng Kung University play an important role. I hope that during the anniversary next year, we can expand and gather related forums on campus to promote more exchanges from all walks of life.

Chairman Wu Minqiu of Macronix Electronics, who serves as the chairman of the Chengdu Cultural and Educational Foundation, said in his speech that the application of smart manufacturing combined with AI is very important to promote the growth of Taiwan's industrial chain. He returned to Taiwan to start a business 37 years ago and developed the world's first fully computerized semiconductor production line. He also created the first AI system to apply Data big data to semiconductors, thereby greatly improving the quality of Taiwan's manufacturing. Macronix's high-quality products have been verified by the world-class aerospace industry, and low-orbit satellites were the first to adopt Macronix's high-quality products. The Chengdu Forum discusses the most important scientific and technological issues every year. This year has been held for the fifth time. The Macronix Golden Silicon Award organized by the Macronix Education Foundation has also been held for 25 consecutive years. It is great to see the continuous growth of young students who have been continuously cultivated. I hope that through the holding of these industry-university exchange activities, students can absorb more new knowledge and cultivate innovation, explore new technological applications in the next 50 years, and give back to Taiwan's industry and society.

Chen Qihong, chairman of Qisida Group, currently serves as the chairman of the National Cheng Kung University Global Alumni Association. He said that during the 2026 anniversary of the school, he will find ways to connect various departments to hold a semiconductor industry forum to expand influence and let Taiwan see National Cheng Kung University and let the world see Taiwan. He then shared the theme of "The Bright Future of Smart Manufacturing" and shared the future AI trends and the layout focus of smart manufacturing. Chen Qihong said that Taiwan has an important position in the global manufacturing industry, and it should make good use of its data advantages, grasp the AI wave, and use robots and virtual reality integration to create a bright future for smart manufacturing. Chen Qihong pointed out that the essence of smart manufacturing is not just automation, but real-time monitoring, analysis and decision-making by AI to achieve autonomous operation.

Sun Hong, chairman and president of Mengli Group, pointed out that under the wave of digital transformation, the manufacturing industry is undergoing a paradigm shift from automation to intelligence. Enterprises use data-driven and Internet of Things (IoT) technologies to realize real-time monitoring and analysis of big data, and combine artificial intelligence (AI) and machine learning (ML) for predictive maintenance, quality control and production optimization to improve production line efficiency and safety. Virtual-real integration uses digital avatar technology to create virtual models of products, processes or factories, allowing companies to remotely optimize production, reduce costs and accelerate product launches through simulation, testing and prediction. Mengli Group is actively deploying smart manufacturing and virtual and real integration to create a flexible, efficient and customized new production ecology. In the future, the competitiveness of enterprises will depend on their degree of digitization and the ability to integrate virtual and real entities to embrace an intelligent future and create new value for sustainable development.

Cai Qingxiong, deputy general manager of Delta's Electrical and Electronics Business Group, shared that since 2015, Delta Electronics has actively promoted smart manufacturing and comprehensively improved production efficiency and quality through digital technology. In the early stage, a "top-down" strategy was adopted. Goals were set and the current situation was taken stock of. A dedicated execution team was established to plan for phased promotion: "rationalization, automation, digitalization, and intelligence." The goals that could be achieved at each stage were clearly defined. Adhering to the "people-oriented" concept, Delta is committed to allowing employees to engage in more value-creating work, gradually promoting "machine substitution" to reduce direct manpower requirements, and at the same time building an automated intelligent production line design platform to improve the return on investment (ROI) of indirect personnel.

Ma Dakang, general manager of Google Chrome OS R&D, the 2025 National Cheng Kung University 114th Annual Alumni Outstanding Achievement Award winner, introduced Google’s innovation in generative AI, and also introduced “Google’s university exchange program in Taiwan” and many cooperation with National Cheng Kung University. He mentioned that with the rapid development of generative AI, the R&D, design and manufacturing of many new AI cloud and terminal chips are continuing. Taiwan is in a favorable competitive position in semiconductor manufacturing, AI Server, data centers and other fields. In terms of software, Google's latest large-scale language model Gemini is Google Most Capable AI Built for the Agentic AI Era. It has the functions of independent intelligence and independent decision-making, and is an innovation in the direction of Agentic AI services.

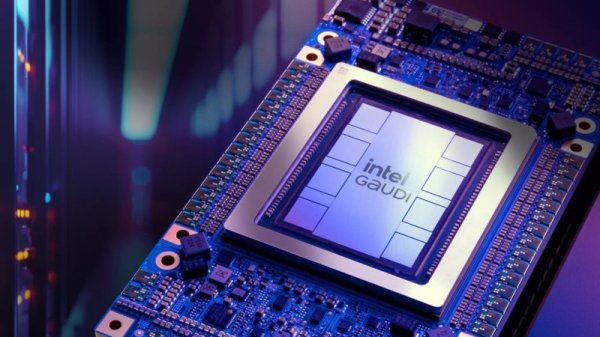

Lin Jiancheng, senior deputy general manager of Advanced Micro Devices (AMD) Taiwan Commercial Business Division, said that the AI wave is coming, and artificial intelligence innovation is accelerating in various fields at an unprecedented speed. Various applications continue to evolve, and the trend of huge training or inference models and generative AI poses higher challenges to computing performance and development efficiency. How to adopt more reasonable and effective solutions and speed up the time to productization has become an important issue for Taiwan's industry and developers.. Because AMD can provide the industry's most complete end-to-end AI computing product portfolio, covering all levels of the AI technology stack, from data centers to edge computing to personal devices.

Finally, NVIDIA (NVIDIA) senior data scientist Liu Guanliang shared that the "big explosion" era of generative artificial intelligence in the physical world has arrived. He mentioned that the so-called Physical AI refers to a model that can understand and interact with the physical world. This model is leading the industry from traditional rule-based and static automation to intelligent and adaptable autonomous systems. "This revolution will redefine the global industrial ecology, affecting industrial fields with a GDP of up to 50 trillion US dollars. From warehousing, factories to transportation systems, and even the robots and self-driving vehicles that work side by side with us, they will become smarter and more efficient.